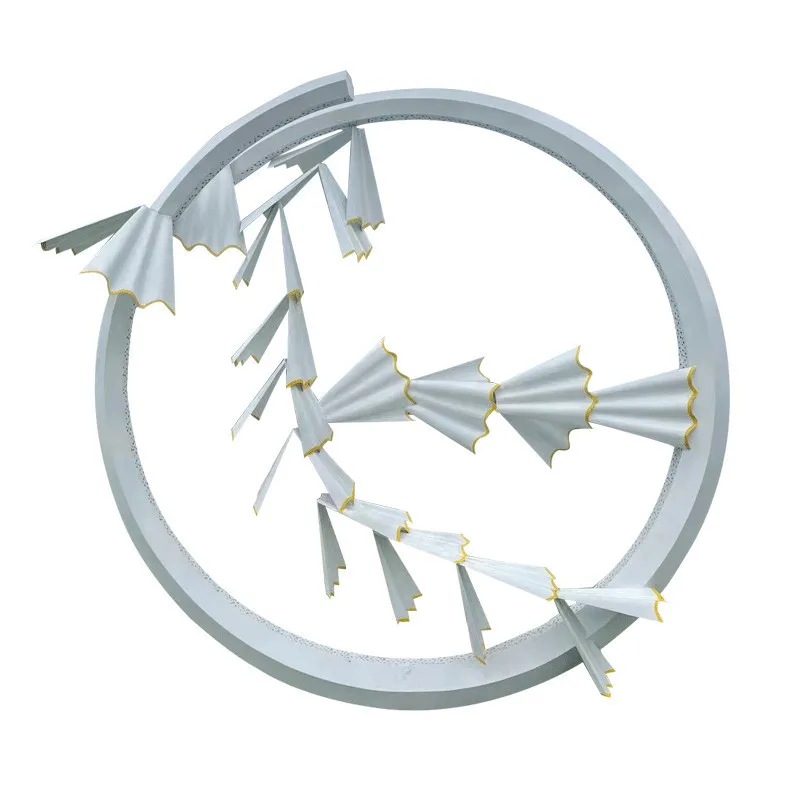

stainless steel sculpture manufacturers

Stainless steel sculpture manufacturers represent the pinnacle of artistic engineering, combining traditional craftsmanship with modern manufacturing capabilities. These specialized firms utilize advanced metallurgical techniques and cutting-edge fabrication processes to create stunning works of art that withstand the test of time. Their facilities are equipped with state-of-the-art CNC machinery, precision welding equipment, and surface finishing technologies that enable the creation of both small-scale decorative pieces and monumental public installations. The manufacturing process involves careful material selection, typically focusing on high-grade 304 and 316 stainless steel for optimal durability and aesthetic appeal. These manufacturers employ skilled artisans and engineers who work collaboratively to transform conceptual designs into tangible masterpieces. They offer comprehensive services including 3D modeling, prototype development, custom fabrication, and installation support. The production capabilities extend to various finishing options, from mirror-polished surfaces to brushed textures, allowing for diverse artistic expressions. These manufacturers also prioritize quality control measures, ensuring each sculpture meets strict structural integrity standards while maintaining artistic vision.