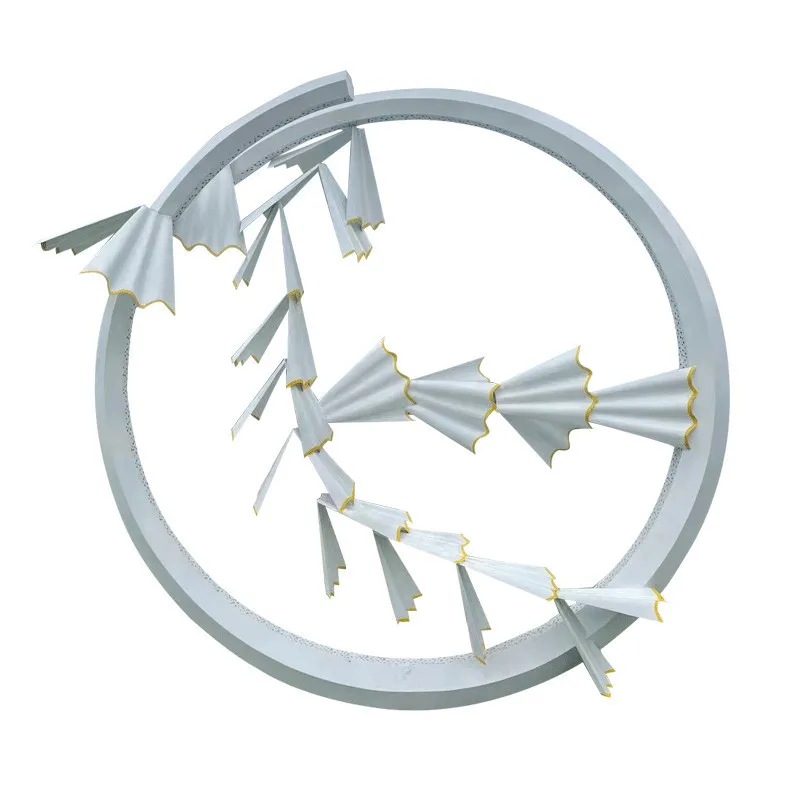

скульптура из пены для резьбы

Резьба по пенопласту представляет собой революционный подход в мире художественного выражения и профессионального моделирования. Этот универсальный материал состоит из высокоплотного полиуретанового пенного материала, специально разработанного для детальной резьбы и скульптуры. Материал обладает исключительной технологичностью, позволяя художникам и дизайнерам создавать сложные трехмерные изделия с поразительной точностью. Уникальная молекулярная структура пены обеспечивает оптимальное сопротивление для контролируемого реза, сохраняя при этом конструктивную целостность на протяжении всего творческого процесса. Художники могут легко формировать материал с помощью стандартных инструментов для резьбы, тепловых устройств или специализированного оборудования для резки пены. Закрытоячеистая структура пены гарантирует минимальное образование пыли во время резьбы, делая ее более чистой и безопасной альтернативой традиционным материалам для скульптуры. Особо стоит отметить, что пена для резьбы сохраняет размерную устойчивость при различных температурах и уровнях влажности, обеспечивая долговечность готовых изделий. Материал принимает широкий спектр покрытий, включая краски, покрытия и герметики, что позволяет использовать различные методы обработки поверхности и эффекты. Профессиональные применения охватывают множество отраслей, от создания архитектурных моделей и разработки прототипов до изготовления театральных реквизитов и образовательных демонстраций. Легкий вес пены делает ее идеальной для крупномасштабных установок, а ее прочность гарантирует, что готовые изделия сохраняют свою форму во время транспортировки и экспозиции.