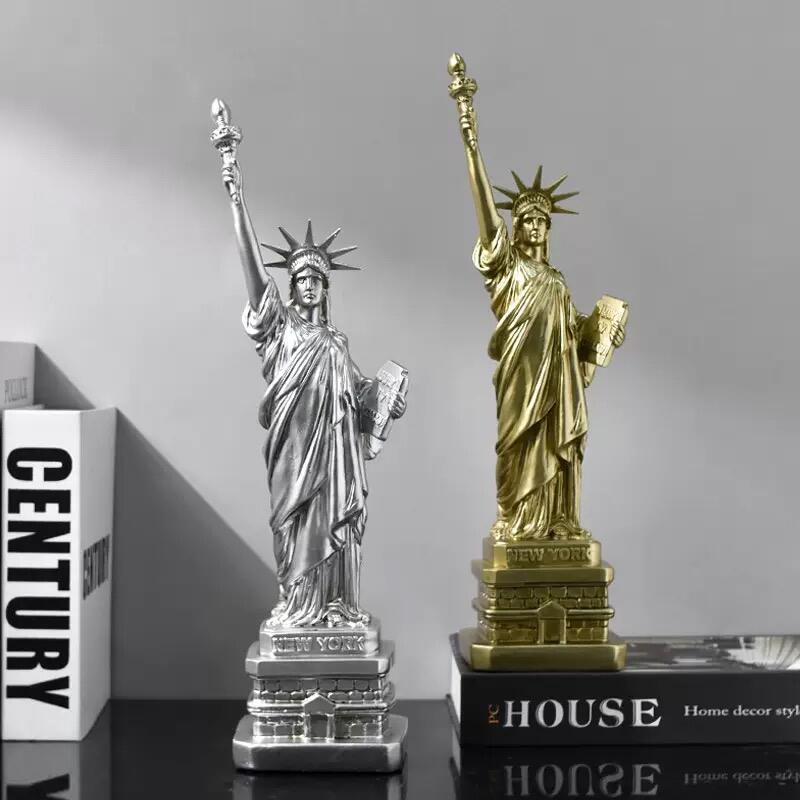

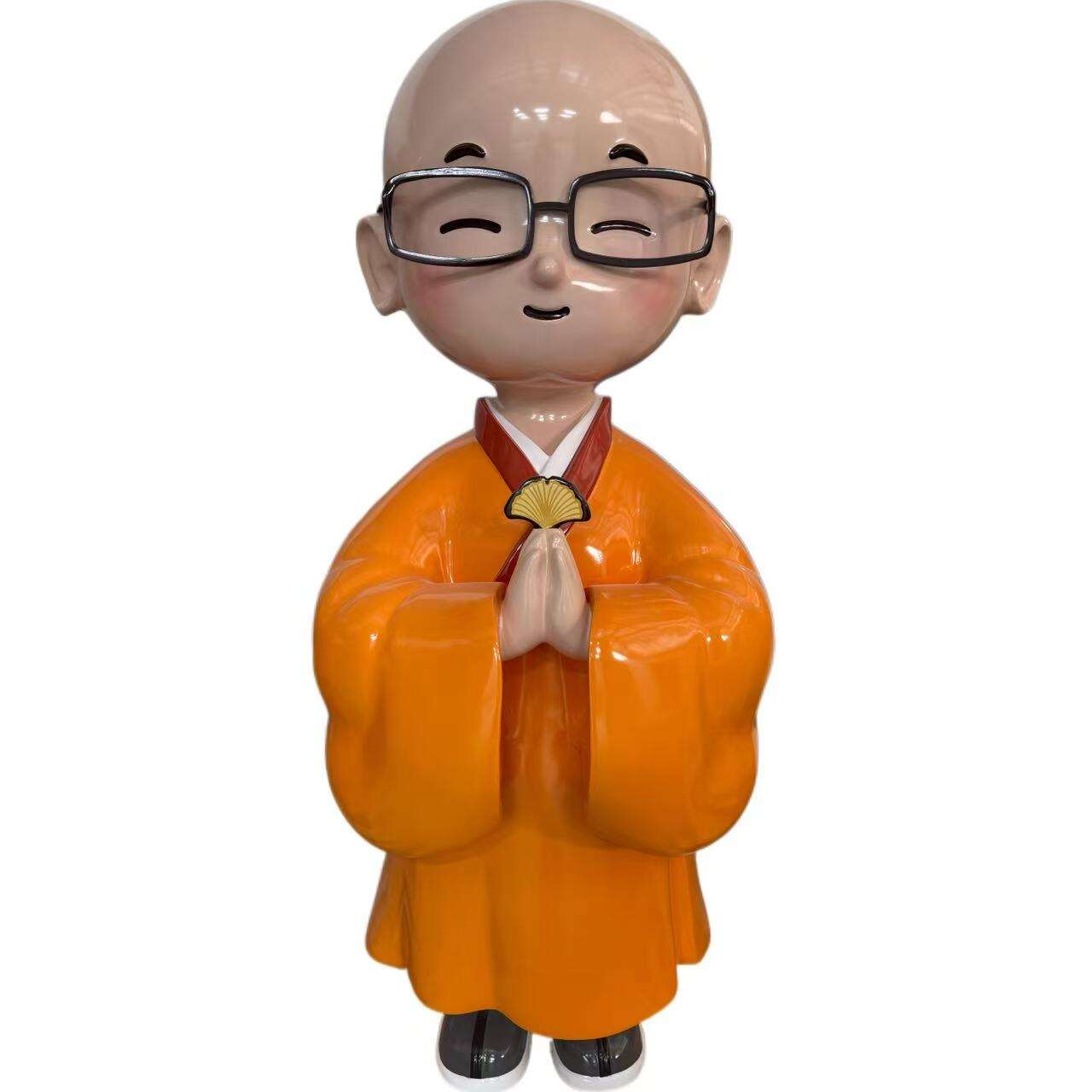

fiberglass sculpture fabrication

Fiberglass sculpture fabrication is a versatile and innovative process that combines artistic vision with advanced manufacturing techniques. This method involves creating durable, lightweight sculptures using glass fiber reinforced plastic materials. The process begins with designing and creating a mold, followed by laying down multiple layers of fiberglass mat or cloth, which are then saturated with polyester or epoxy resin. The fabrication process allows for intricate details and complex shapes while maintaining structural integrity. Modern fiberglass sculpture fabrication incorporates advanced technologies such as 3D modeling software for precise design planning and computer-controlled cutting systems for accurate material preparation. The resulting sculptures are weather-resistant, making them ideal for both indoor and outdoor installations. The technology enables artists and manufacturers to produce sculptures of varying sizes, from small decorative pieces to monumental public art installations. The process also allows for the integration of different finishing techniques, including painting, coating, and texturing, providing endless possibilities for artistic expression and customization.