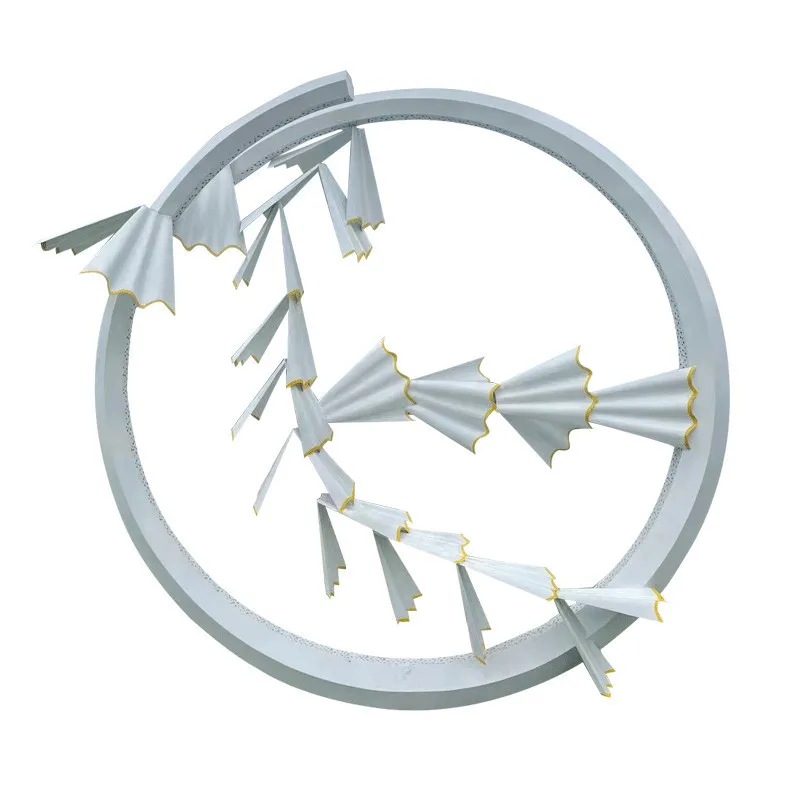

making foam sculptures

Making foam sculptures is an intricate artistic process that combines creativity with technical precision. This versatile craft involves transforming expandable foam materials into stunning three-dimensional artworks through careful shaping, carving, and finishing techniques. The process begins with selecting appropriate foam materials, typically polyurethane or polystyrene, which offer excellent workability and durability. Artists use various tools including hot wire cutters, rasps, sandpaper, and specialized foam sculpting tools to shape the material into desired forms. The technology behind foam sculpture making has evolved significantly, incorporating computer-aided design (CAD) for precise planning and modern coating systems for enhanced durability. These sculptures find applications in numerous fields, from theatrical props and theme park installations to architectural decorations and contemporary art pieces. The process allows for both small-scale detailed works and massive installations, making it particularly valuable for creating lightweight yet visually impressive structures. Advanced coating technologies enable these sculptures to withstand various environmental conditions, making them suitable for both indoor and outdoor display. The making of foam sculptures has revolutionized the way artists and designers approach large-scale three-dimensional artwork, offering a cost-effective and efficient alternative to traditional sculpting materials.